Safe drainage systems for industrial applications

HAURATON provides high-quality surface drainage solutions suitable for a range of industries. With superior lateral force resistance, easy access for cleaning and quick installation, HAURATON drainage solutions are more stable, durable and hydraulically efficient and are ideal for use in heavily trafficked environments.

Industrial drainage solutions from HAURATON

When choosing the correct system for your project, it can be quite overwhelming. There are many factors to consider regarding the design and installation, for example heavy loads, frequency of traffic, storm events, local planning and client requirements.

HAURATON have the experience to provide the most appropriate and cost-effective solution to meet your project requirements. Close and comprehensive technical support is available during all stages of the project, from early planning and design, on-site installation and maintenance advice. Get in touch to discuss your project.

–

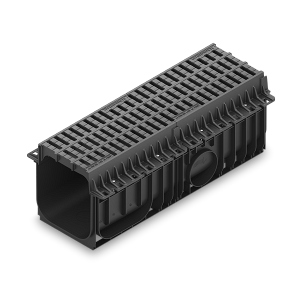

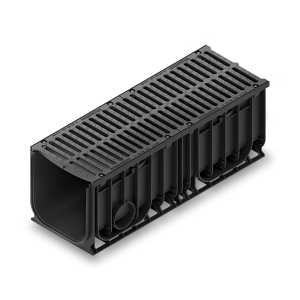

Moulded as an integral part of the channel body

Ductile iron slotted top

Cast top with lateral concrete anchoring

Ductile iron

– Constant depth

– Stepped fall

– Step fall (for NW 200)

– Hydraulic gradient

– Constant depth

– Stepped fall

– Radial installations possible

– Large channels for retention

– Channel run without slotted top achievable, for example, under planted areas

– Cable installations can be threaded though throat voids of the channel

-Material combination of recycled PP and ductile iron for adaptability on the construction site and robustness

-Side wings for optimum connection to the concrete surface

-No screws and loose parts on the surface

-Connection between channel and cover encased in concrete for extra safety

– Channel and cover = one component

– Self-centring screw –> automatically finds the correct position

– Polypropylene channel body can be easily machined on site

Industrial drainage project

Challenges with industrial drainage

To ensure the smooth operation of warehouses and distribution centres, drainage channels must meet the following challenges in particular:

- High loads & forces

Constant heavy-duty traffic imposes significant dynamic forces on the drainage channels due to braking, turning, accelerating and crossing over. The drainage systems need to be strong and durable in order to withstand the loads and forces.

- High flow rates

Especially during heavy rainfall events, high volumes of water must be drained off the surface over a short time to protect goods, equipment and the operational industrial area from flooding. Surface drainage systems therefore require efficient intake and appropriate channel sizing through accurate hydraulic calculation.

Further requirements for industrial drainage systems:

Efficient interception & high drainage capacity

Cost-effective & safe drainage solution

Easy & quick installation with low long-term maintenance costs

Contact our drainage experts

HAURATON’s drainage systems meet all the requirements for the drainage of warehouses and distribution centres. We not only offer you the right product for your industrial drainage, but also support you with hydraulic calculations and installation on site. Contact our drainage experts!