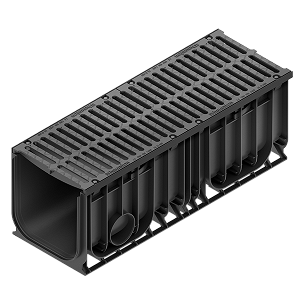

Load class according to EN 1433

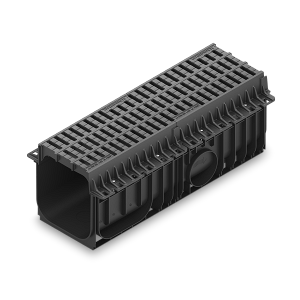

Load class according to EN 1433

up to F 900

up to F 900

up to F 900

up to E 600

up to F 900

Nominal width | System size

Nominal width | System size

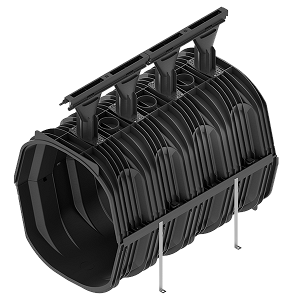

1000, 2000, 3000, 5000, 8000, 10000

200, 300

100, 150, 200, 300, 400, 500

100, 150, 200, 300, 400

300, 400, 500

Materials of the lower parts

Materials of the lower parts

Modified polypropylene (PP), 100 % recycled composite

Modified polypropylene (PP), 100 % recycled composite

Fibre-reinforced concrete

Modified polypropylene (PP), 100 % recycled composite

Fibre-reinforced concrete or polypropylene (PP)

Angle housing

Galvanised steel or ductile iron edge rail with 40 x 40 mm insertion depth

Moulded as an integral part of the channel body

Depending on the version with FASERFIX or RECYFIX:

Galvanised steel or cast iron frame with 40 x 40 mm insertion depth

Grating variants

Ductile iron grating with lateral concrete anchoring

– Ductile iron gratings

– GUGI ductile iron gratings

Gradient

– Constant depth

– Stepped fall

– Stepped fall (at NW 200)

– Constant depth

– Constant depth

– Built-in fall (150, 200, 300)

– Stepped fall

– Constant depth

– Stepped fall

Special characteristics

– Radial installations possible

– Large channels for retention

– Channel run without slotted top achievable, for example, under planted areas

– Cable installations can be threaded though throat voids of the channel

– Material combination of recycled PP and ductile iron for adaptability on the construction site and robustness

– Side wings for optimum connection to the concrete surface

– No screws and loose parts on the surface

– Connection between channel and grating encased in concrete for extra safety

– SIDE-LOCK, boltless locking system

– 16 fixing points for grating/metre

– Channel and cover = one component

– Self-centring screw –> automatically finds the correct position

– Polypropylene channel body can be easily machined on site

– Rainwater treatment by surface filtration

– DIBt approval

– Proprietary treatment system: CIRIA SuDS Manual C753 chapter 14