Load class according to EN 1433

Load class according to EN 1433

up to F 900

up to F 900

up to E 600

Nominal width | System size

Nominal width | System size

100, 150, 200, 300, 400, 500

1000, 2000, 3000, 5000, 8000, 10000

100, 200, 300, 400, 500

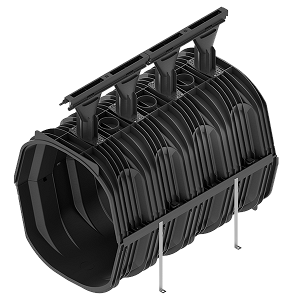

Materials of the lower parts

Materials of the lower parts

Fibre-reinforced concrete

Modified polypropylene (PP), 100 % recycled composite

Modified Polypropylene (PP) or fibre-reinforced concrete

Angle housing

Galvanised steel or ductile iron edge rail with 40 x 40 mm insertion depth

Grating variants

– Ductile iron gratings

– GUGI ductile iron gratings

Retained ductile iron slotted top

Gradient

– Constant depth

– Built-in fall (150, 200, 300)

– Stepped fall

– Constant depth

– Stepped fall

Special characteristics

– SIDE-LOCK, boltless locking system

– 16 fixing points for grating/metre

– Radial installations possible

– Large channels for retention

– Channel run without slotted top achievable, for example, under planted areas

– Cable installations can be threaded though throat voids of the channel

SIDE-LOCK, boltless locking mechanism