Load class according to EN 1433

Load class according to EN 1433

up to F 900

up to F 900

up to C 250

up to F 900

A 15

A 15

E 600

up to SLW 60

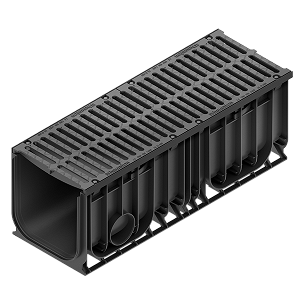

Nominal width | System size

Nominal width | System size

200, 300, 400, 500

100, 150, 200, 300

100, 150, 200, 300

100, 150, 200, 300, 400, 500

115, 135, 155, 205, 255

115, 135, 155, 205, 255

100, 150, 200, 300, 400

Materials of the lower parts

Materials of the lower parts

Fibre-reinforced concrete or polypropylene (PP)

Fibre-reinforced concrete

Polypropylene (PP), 100 % recycled composite

Fibre-reinforced concrete

Galvanised or stainless steel

Galvanised or stainless steel

Polypropylene (PP), 100 % recycled composite

Polypropylene

Angle housing

Depending on version with FASERFIX or RECYFIX:

Galvanised steel or ductile iron edge frame with 40 x 40 mm inlay depth

Galvanised or stainless steel edge frame with 20 x 20 mm inlay depth

Composite edge frame with 20 x 20 mm inlay depth

Galvanised steel or ductile iron edge frame with 40 x 40 mm inlay depth

Integrated edge frame (part of the channel body) with longitudinal slide protection

Grating variants

- Ductile iron slotted gratings

- GUGI ductile iron mesh gratings

- Slotted gratings

- Reinforced Slotted gratings

- Longitudinal gratings

- Mesh gratings

- FIBRETEC Design Slotted gratings

- METROPOLIS Design ductile iron gratings

- Ductile iron gratings

- Perforated gratings

⇒ Made of ductile iron, composite, galvanised steel, stainless steel

- Longitudinal gratings

- GUGI Composite Mesh gratings

- Mesh gratings

- FIBRETEC Design Slotted gratings

- Reinforced Slotted gratings

⇒ Made of ductile iron, composite, galvanised steel, stainless steel

- Ductile iron slotted gratings

- GUGI ductile iron mesh gratings

- Slotted gratings

- FIBRETEC Design Slotted gratings

- Mesh gratings

- Longitudinal gratings

- Perforated gratings

⇒ Made of composite, galvanised steel, stainless steel

- Slotted gratings

- FIBRETEC Design Slotted gratings

- Mesh gratings

- Longitudinal gratings

- Perforated gratings

⇒ Made of composite, galvanised steel, stainless steel

Application area

- Platforms

- Station forecourt

- Platforms

- Station forecourt

- Platforms

- Station forecourt

- Platforms

- Station forecourt

Special characteristics

- Rainwater treatment through surface filtration

- Plannable in accordance with KECO approval

- Proprietary treatment system: CIRIA SuDS Manual C753 chapter 14

- Large retention volume

- Extremely low maintenance

- Boltless quick-locking system SIDE-LOCK

- 10-fold locking option of the grating per metre

- Fire resistance class A1 (non-combustible) in accordance with DIN 4102

- Pre-assembled ready for installation – channel and grating = one component

- Low weight

- Channel body made of (polypropylene) can be easily machined, cut and drilled on site

- High frost, de-icing salt and UV resistance

- 100 % corrosion-free

- Boltless quick-locking system SIDE-LOCK

- 16-fold locking option of the grating per metre

- Factory-made cross and T-elements possible

- Channel in closed design

- Design based on standards & guidelines

- Channel in flat design possible

- Perforation in the base of the drain element – on-site connection

- Height adjustment

- Perforation in the base – on-site connection

- Channel and grating = one product

- Self-centring screw -> automatically finds the correct position

- Polypropylene channel body can be easily machined on site

- Low space requirement due to possible installation in a block network

- 95% storage capacity

- Connection possibility to DRAINFIX CLEAN filter substrate channel for rainwater treatment