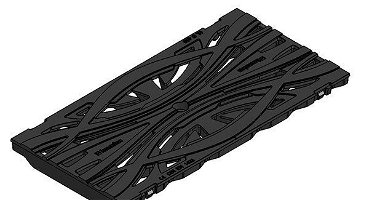

The terms line drain or linear drainage are used when referring to drainage channels. This has an enclosed channel gully with a grating or slot inlet at surface level. Several drainage channels are installed together in one channel run to collect, transport and discharge surface water into underground sewer networks, sustainable drainage systems or other local water systems.

Advantages of linear drainage:

-

Achieves efficient intake, drainage and transmission of surface water with a continuous interception along the channel run

-

Provides effective drainage for large catchment areas with a quick, easy and cost-effective installation

-

Simple and practical to clean and maintain: allows full access with low long-term maintenance costs

-

High-quality aesthetic appearance; system features can add design value