What are the special features of FASERFIX concrete?

FASERFIX concrete is:

FASERFIX concrete is produced in a resource-conserving manner with defined processes at the HAURATON plant in Ötigheim. The main ingredients of sand, gravel, water and cement are procured via short transport routes from local producers. The basalt fibres are extruded into filaments from melted raw material, in this case, natural volcanic rock.

FASERFIX concrete is fully recyclable. The process of concrete quarrying is carried out by crushing and screening technologies. This results in aggregates that are reused in the construction industry, e.g. as secondary raw material in concrete production, in road construction or as a binder in oil spills.

Concrete is an extremely durable material and can withstand exposure to surface areas where aggressive liquids (diesel, petrol, oil or corrosives) are present e.g. petrol station forecourts, logistic areas or coastal areas.

Fibre-reinforced concrete has a higher tensile strength with a lower tendency to crack than concrete without fibres. The use of basalt fibres gives FASERFIX impact resistance and fracture strength to encounter extreme heavy loads over a long period.

Concrete provides effective fire protection. Concrete cannot burn and does not liquefy even when it is exposed to high temperatures. In the event of a fire, concrete components can offer maximum safety by containing or preventing the spread.

Your benefits with FASERFIX

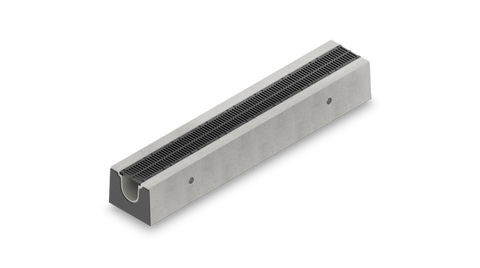

High load capacity

- Fibre-reinforced concrete has extreme strength, durability and resistance

- High-performance frame and recessed cover (product-dependent) ensures a stable connection between grating and channel body

- Unique grating to edge-frame connection (additional protection against longitudinal/lateral movements)

- Proven structural design for superior resistance to heavy loads and dynamic forces

- Gratings up to class F 900

Secured performance

Durability

High stability

- Resistant to environmental influences such as frost, saline conditions, high humidity, extreme temperatures, strong UV radiation and corrosive substances

- Increased impact and wear resistance, due to basalt fibres

- Fire resistance class A1 (non-flammable) according to DIN 4102

- Temperature stable; climate operating temperatures from -25°C to +200°C

Secured quality

Secured performance

Cost minimization

Secure installation

- 90 % time savings with SIDE-LOCK edge-rail design for quick grating removal/replacement during maintenance

- Channel units have thicker sidewalls; reduced dimensions regarding concrete encasement

- Strong, impact resistant units; no breakages during transport, site storage or installation

Time saving

Safety

Design flexibility

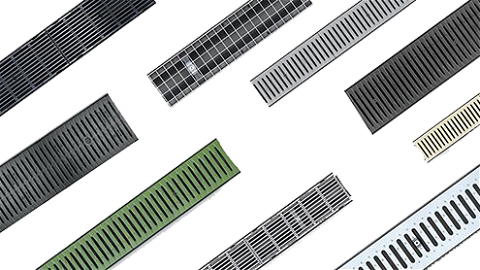

- Numerous grating options are available in different materials such as; ductile iron, composite, galvanised or stainless steel

- Narrow slot width available for pedestrian areas

- Available in 6 different nominal diameters from 100mm to 500 mm

Design flexibility

Uniqueness

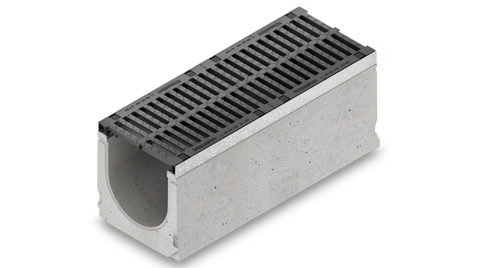

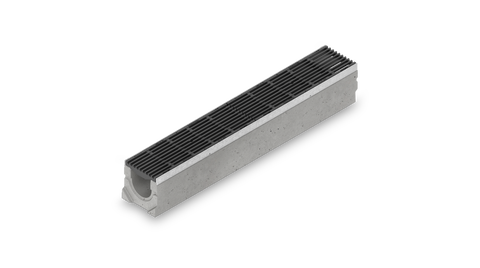

FASERFIX BIG BL

FASERFIX SUPER

FASERFIX KS

FASERFIX STANDARD

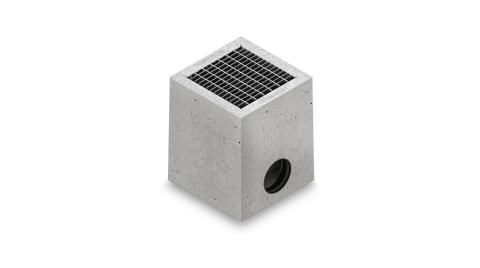

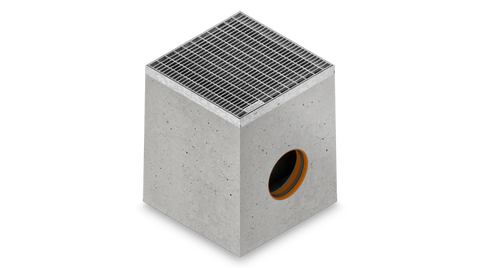

FASERFIX POINT STANDARD

FASERFIX POINT KS

HAURATON expertise

HAURATON’s drainage experts will be happy to advise you on the appropriate FASERFIX product for your project. They can also support you on the hydraulic performance calculation, installation details, through to project completion. Get in touch to speak to an expert.