Your benefits with STEELFIX SLOT

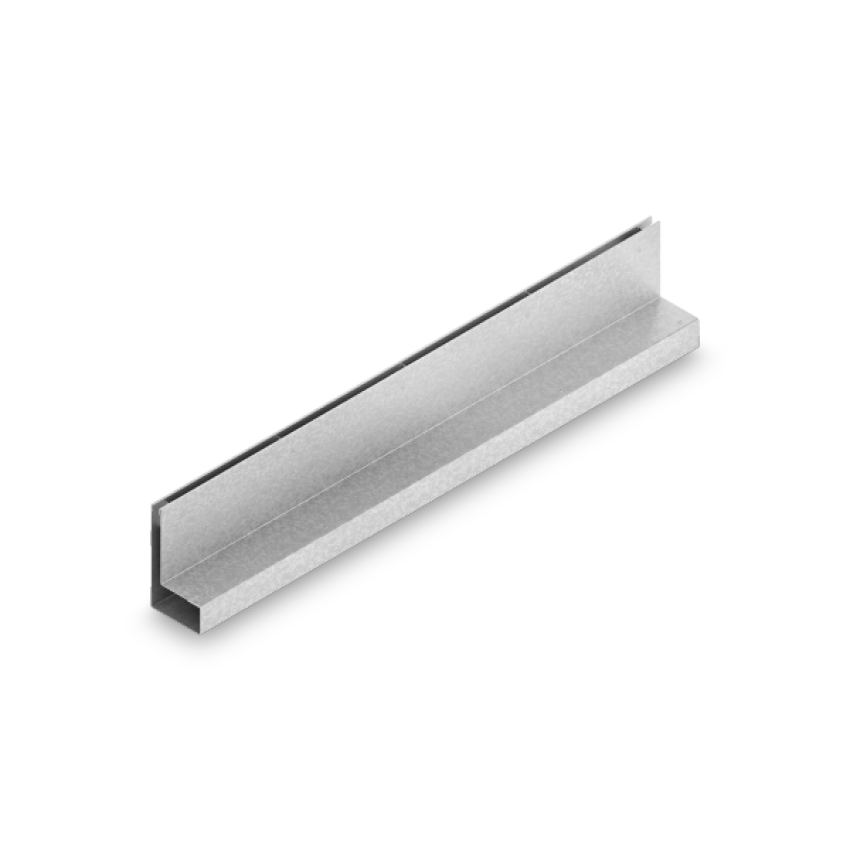

The STEELFIX SLOT product range offers a wide variety of monolithic slotted channels. Depending on the requirement, very different projects can be realised; from pedestrian areas in elegant town squares to revolving entrance doors. STEELFIX SLOT channels are available in two defined dimensions (construction height 150 mm or 180 mm and neck height 100 mm or 130 mm). In addition, there are radial versions and completely customised versions made to measure.

-

Discreet surface drainage for areas with high visual requirements

-

Large number of variants possible (straight, radial, closed, perforated or customised)

-

Available in various types of steel (stainless steel, galvanised steel, corten steel)

-

Access boxes can be positioned variably on the channel run for cleaning and maintenance

- Discreet surface drainage for surfaces with low installation height

- Closed design, perforated on one or both sides

- Access boxes can be positioned variably on the channel run

- Great flexibility in length, width, height and slot width

- Closed, perforated on one or both sides

- Can be customised for cross and T-pieces

High-quality materials and material variants

High-quality materials give HAURATON’s customised channels their unique appearance and ensure reliable, long-term functionality.

Customised stainless steel channels are made of stainless chrome-nickel steel in material grades 1.4301 (V2A) and 1.4571 (V4A). This makes them corrosion-resistant.

Hot-dip galvanising is a particularly durable and cost-effective form of corrosion protection and offers advantages that are unique in corrosion protection technology. Hot-dip galvanised surfaces are not only protected against wind and weather, but also optimally protected against mechanical loads – for decades. Under normal conditions, hot-dip galvanising protects against corrosion for up to 50 years and even under higher loads, the protection period is usually more than 25 years.

Corten steel is a steel alloy that is characterised by its high resistance to weathering. Its surface is coated with a particularly dense layer of iron oxide, which is responsible for its high rust resistance: it acts as a barrier layer and gives the product the desired rust-red appearance.

In addition to the material, you can also choose between different surface finishes: Ground, sandblasted, polished, glass bead blasted, stained or coated. This means that the appearance of the drainage system can be customised to meet the aesthetic requirements of your project.