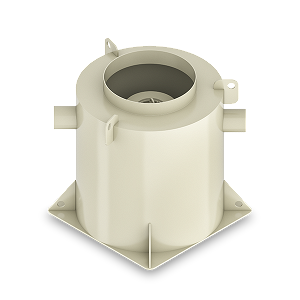

The principle of the separators is based on the combined action of gravity and the coalescence phenomenon. As they pass through the coalescing media, oil and petrol particles stick to it. As more droplets accumulate, they aggregate into larger agglomerates, break away from the filter cartridge and float to the surface of the tank, where they remain until they are removed during periodic cleaning. The use of a coalescing cartridge significantly increases the effectiveness of rainwater treatment.