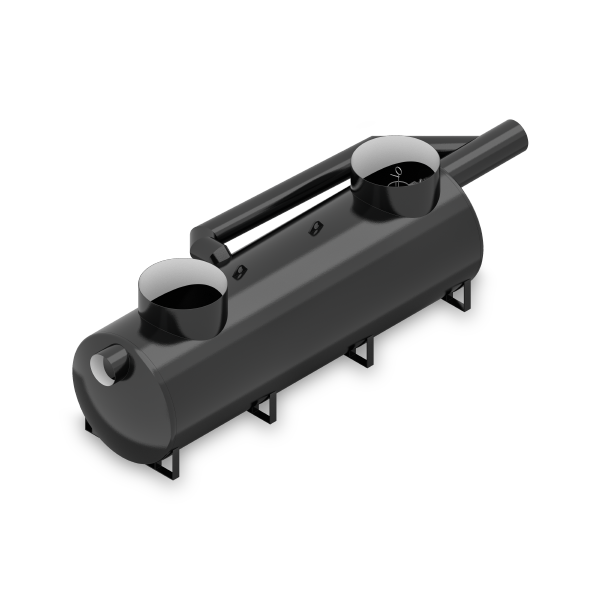

Our solutions – your benefits – AQUAFIX steel oil/water separators integrated settling tanks

High-capacity steel separators are most often used in areas where there is a very high volume of polluted wastewater run-off. The water flowing out of the separator is cleaned to a high degree in accordance with EN 858. The separator is made of St3S steel with a minimum thickness of 6 or 7 mm. The inner surfaces of the separator tank are protected with a coating resistant to substances contained in rainwater. The external surface of the separator tank is protected against corrosion.

-

Tank protection coatings inside and out

-

Wide capacity range from 15 to 4000 l/s

-

Units available with 5- and 10-fold bypass

-

Integrated settling tank

-

Complies with EN 858

-

Separation chamber equipped with a multi-stream coalescing filter

Construction of steel oil separators

Each tank has 2 manholes with a diameter depending on the model (separators with a diameter of 1,250 mm have manholes with a diameter of 625 mm, others with a diameter of 1,000 mm). The separators are not equipped with manhole covers. The internal tank is divided by appropriately shaped baffles into three chambers: a settling chamber, a flotation chamber equipped with a multi-pass coalescing filter and an outflow chamber. All separators are equipped with a siphoned discharge element and a float, which acts as an automatic shut-off to prevent the outflow of accumulated oil substances in the separator when their permitted thickness is exceeded.

Areas of application for AQUAFIX steel separators

Steel hydrocarbon separators are capable of handling large rainwater flows and are therefore used in areas with large catchment areas, such as roads, airports, factories or logistics centres.