Requirements for an industrial drainage system

What characteristics should a drainage system have to guarantee a smooth operation?

1. Extreme loads and dynamic forces

Industrial /logistic facilities can create a very demanding environment for surface drainage systems. Constant traffic by HGVs and forklifts impose immense pressure and force on the channels/gratings.

Linear drainage is not only exposed to heavy loads but also dynamic forces caused by vehicles braking, turning and accelerating when trafficking the surface area.

System design, materials and installation need to be strong, highly stable and secure in order to withstand heavy loads and dynamic forces.

2. High capacity

Industrial and logistic facilities are ever-increasing in size and scale to achieve cost-effective and efficient production and distribution.

For cost-efficient and reliable drainage of extensive external surface areas, high-capacity channel systems are increasingly preferred to achieve savings for the client regarding installation of drainage in operational areas.

3. High flow rates

Extensive areas can generate high volumes of surface water. Unpredicted heavy rainfall can overwhelm drainage systems if they are not designed to accommodate climate changes.

Surface drainage systems require efficient intake and appropriate channel sizing through accurate hydraulic calculations to ensure the surface area will be effectively drained and maintain profitable operations for the client.

4. Contaminated surfaces

Industrial surfaces can become contaminated during day-to-day operations. Tyre wear (microplastics), brake dust, fuel hydrocarbons as well as petrol, oil and other contaminants can be present on the surface without any knowledge.

A combined drainage and filtration system can treat surface water at source before it is released back into sewer systems or watercourses.

”With so many large industrial areas being built, it is essential that surface water drainage is handled effectively to prevent flooding. We can assist with the design process, conception to completion and value engineering options to ensure the best drainage solutions for any situation”.

HAURATON have a range of heavy-duty drainage systems ideal for coping with the demanding environments of civil engineering projects. Click here to find information about our products.

Industrial drainage solutions from HAURATON

When choosing the correct system for your project, it can be quite overwhelming. There are many factors to consider regarding the design and installation, for example heavy loads, frequency of traffic, storm events, local planning and client requirements.

HAURATON have the experience to provide the most appropriate and cost-effective solution to meet your project requirements. Close and comprehensive technical support is available during all stages of the project, from early planning and design, on-site installation and maintenance advice. Get in touch to discuss your project.

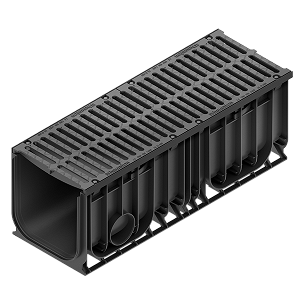

Galvanised steel or ductile iron edge rail with 40 x 40 mm insertion depth

Moulded as an integral part of the channel body

Depending on the version with FASERFIX or RECYFIX:

Galvanised steel or cast iron frame with 40 x 40 mm insertion depth

Ductile iron slotted top

– Ductile iron gratings

– GUGI ductile iron gratings

Ductile iron

Ductile iron grating

– Constant depth

– Stepped fall

– Constant depth

– Built-in fall (150, 200, 300)

– Stepped fall

– Constant depth

– Stepped fall

– Constant depth

– Radial installations possible

– Large channels for retention

– Channel run without slotted top achievable, for example, under planted areas

– Cable installations can be threaded though throat voids of the channel

– SIDE-LOCK, boltless locking system

– 16 fixing points for grating/metre

– Channel and cover = one component

– Self-centring screw –> automatically finds the correct position

– Polypropylene channel body can be easily machined on site

– Rainwater treatment by surface filtration

– DIBt approval

– Proprietary treatment system: CIRIA SuDS Manual C753 chapter 14

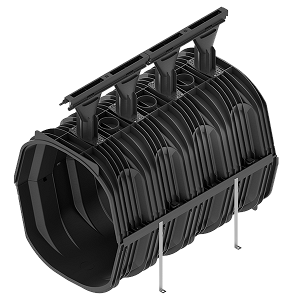

For safe and secure cable routing: SERVICE CHANNEL

The SERVICE CHANNEL provides safe and practical cable management within industrial units and exhibition halls. Cables and wires can easily be threaded into the channel and accessed as and when required. The SERVICE CHANNEL can withstand the frequency of high dynamic forces when trafficked.

-

Temporary or permanent management of cables and wires

-

Channels available in recycled composite (polypropylene) or fibre-reinforced concrete for medium to heavy-duty applications

-

Solid covers in ductile iron with removable cable inlets for quick and efficient access

-

A range of channel widths and depths to suit project requirements