Safe precision work within short time

The development of the Silverstone Wing Complex had a construction plan of 54 weeks. The structural components would incorporate a new pit lane, paddock area and garages. Moreover, it would serve as a hospitality space for V.I.P. spectators and include a 4000 m² exhibition space.

Since the main architectural components had taken most of the work, there was a race against time to have the drainage channels installed. Subsequently, a racing event was just around the corner and the foundations needed to be finalised in advance. The channel solution supplied had to have the benefit of a quick installation. Thanks to the close cooperation of all those involved in the project, the installation was completed on time and accurately despite the tight schedule.

HAURATON’s support makes a difference

Throughout the Silverstone development, HAURATON’s project team were on site to make sure operations were running smoothly with the drainage design. HAURATON were able to give contractors and engineers involved in the project the reassurance that our channels would comply with the performance criteria in terms of operational safety, materials, handling and longevity.

Easy to reach the finish line with HAURATON’s drainage solutions

HAURATON were able to reassure the project’s engineers and contractors that the drainage solutions would meet their highest safety standards. This was due to the product solutions, already providing high excellence for safety and stability within another motorsport project.

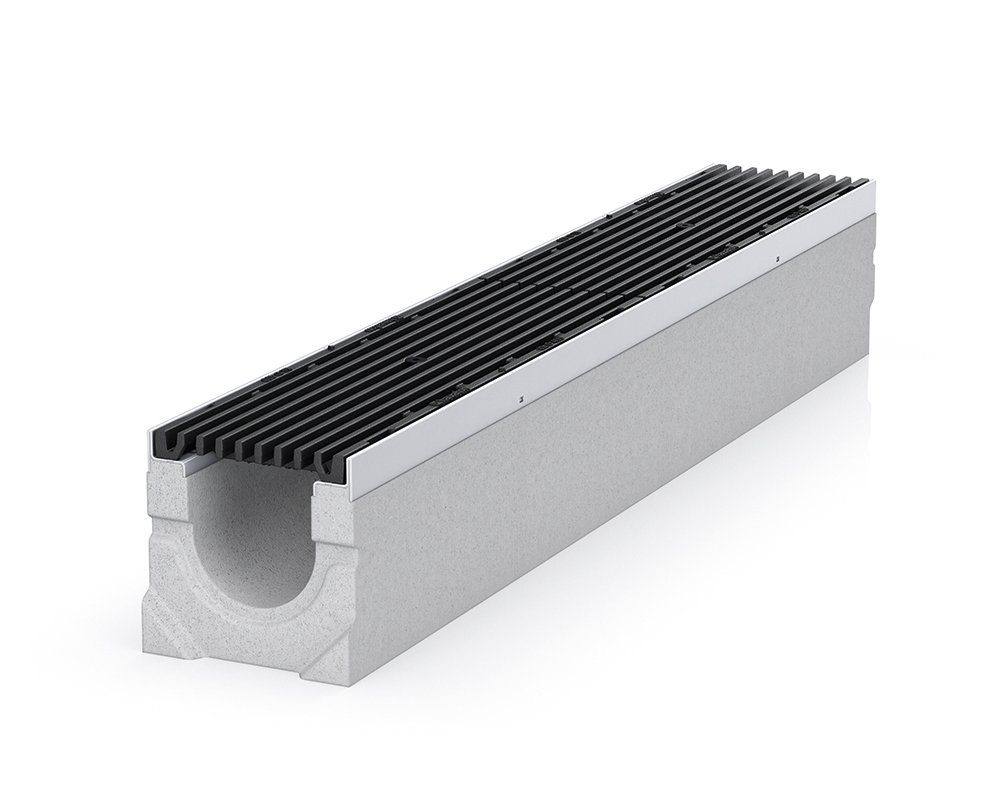

Three of HAURATON’s products were installed for different application areas of Silverstone’s Wing complex.