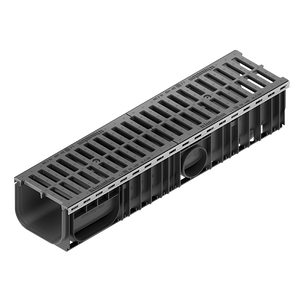

Load class according to EN 1433

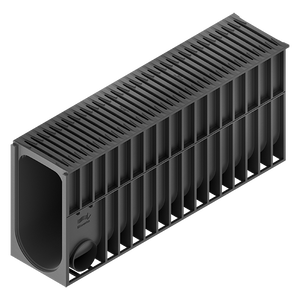

Load class according to EN 1433

up to D 400

up to D 400

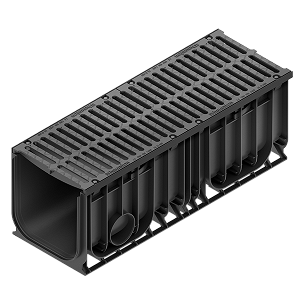

up to D 400

up to E 600

up to F 900

up to F 900

up to F 900

Nominal width | System size

Nominal width | System size

100, 150, 200, 300

100, 150, 200, 300

100 & 200

100, 150, 200, 300, 400

100, 150, 200, 300

1000, 2000, 3000, 5000, 8000, 10000

300 – 500

Materials of the lower parts

Materials of the lower parts

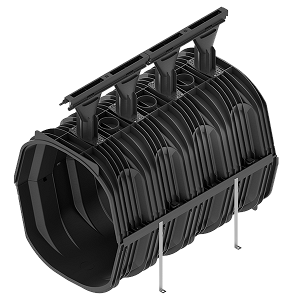

Polypropylene (PP), 100 % recycled composite

Polypropylene (PP), 100 % recycled composite

Modified polypropylene

Modified polypropylene (PP), 100 % recycled composite

Fibre-reinforced concrete

Fiber-reinforced concrete or polypropylene (PP)

Angle housing

Composite frame 20 x 20 mm insertion depth

Integrated edge rail made of galvanised or stainless steel

Moulded as an integral part of the channel body

Galvanised or stainless steel frame with 20 x 20 mm insertion depth

Depending on the version with FASERFIX or RECYFIX:

Galvanised steel or cast iron frame with 40 x 40 mm insertion depth

Grating variants

– Longitudinal bar grating

– GUGI design gratings

– Mesh gratings

– FIBRETEC and METROPOLIS design gratings

⇒ Made of ductile iron, plastic, galvanised steel, stainless steel

– Perforated gratings

– Mesh gratings

– GUGI design gratings

⇒ Made of ductile iron, galvanised steel, stainless steel

Integrated award-winning FIBRETEC heelsafe design

– Design gratings FIBRETEC and METROPOLIS

– Perforated gratings

– GUGI mesh gratings

– Mesh gratings

– Longitudinal bar gratings

⇒ Made of ductile iron, composite, galvanised or stainless steel

Retained ductile iron slotted top

Gradient

– Constant depth

– Stepped fall

– Constant depth

– Stepped fall

– Constant depth

– Stepped fall

– Constant depth

– Stepped fall

– Constant depth

– Built-in fall

– Stepped fall

– Constant depth

– Stepped fall

Special characteristics

– Pre-assembled ready for installation

– Low weight, easy to handle and install

– Channel body can be easily machined, cut to size on-site

– Pre-assembled ready for installation

– Low weight

– Steel edge rail enables straight edge of tarmacked surfaces

– Channel body made of polypropylene can be easily machined, cut, drilled on-site

– Large retention volume despite slim channel design

– Monolithic drainage channel

– Vandalism-proof

– Easy cleaning via the inspection box

– Channel and cover = one component

– Self-centring screw –> automatically finds the correct position

– Polypropylene channel body can be easily machined on site

– SIDE-LOCK, boltless locking system

– Optional bar and bolt fixing per grating

– Radial installations possible

– Large channels for retention

– Channel run without slotted top achievable, for example, under planted areas

– Cable installations can be threaded though throat voids of the channel

– Rainwater treatment by surface filtration

– DIBt approval

– Proprietary treatment system: CIRIA SuDS Manual C753 chapter 14